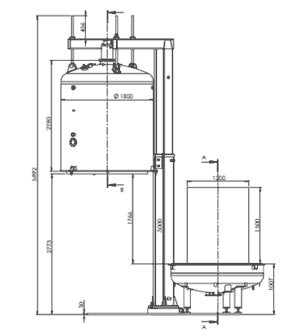

Plasma Nitriding machine

Low cost Plasma Nitriding HPPN – High Pulsed Plasma Nitriding

HPPN nitriding is a very low cost effective way to improve fatigue resistance, resistance on hertz pressure and hot hardness. This process is the most cost efficient treatment for molds and dies for forming, die casting, forging, aluminium extrusion, plastic molding, and various precision components. It offers excellent control for the structure of nitride layers that is required when combining these thermo chemical treatments with PVD and PECVD coating.

Advantages of Plasma Nitriding:

• Extremely low running cost (low energy and gas consumption)

• Flexible and robust process

• Effective control of metallurgical structures

• Special Nitriding process suitable for PVD for dies and molds

• Precision components

Standard sizes:

Standard sizes:

• Bell furnace HPPN 600 x 1000 – 30 kW screen, 30 kW BIAS

• Bell furnace HPPN 1000 x 1000 – 60 kW screen, 30 kW BIAS

• bell furnace HPPN 1200 x 1500 – 90 kW screen, 30 kW BIAS

Individual sizes can be realized.